Steel plants

Specialized in electric arc furnaces, supply of low voltage secondary circuits, regulation and control system and electrical engineering for medium and low voltage.

PRODUCTS FOR THE STEEL SECTOR

GECSA, as a member of the GHI group, a recognized manufacturer of melting and heat treatment furnaces, has more than 30 years of experience in the steel sector. Within these years, it has developed a multitude of projects for the steel sector, mainly for the electric arc furnace, which is responsible for the scrap smelting process through an electric arc generated by graphite electrodes. Within the range of products supplied, the complete low voltage secondary circuit stands out, which is responsible for transmitting the current from the power transformer to the electrodes themselves. As automation engineering, we provide service with the main software brands on the market to any of the controllable parts of the furnace, having its own regulation of electrodes. In the medium voltage area, we are distributors of major European brands in electrical wiring and electrical equipment (vacuum switches, disconnectors …) in addition to carrying out turnkey projects for the installation of transformers.

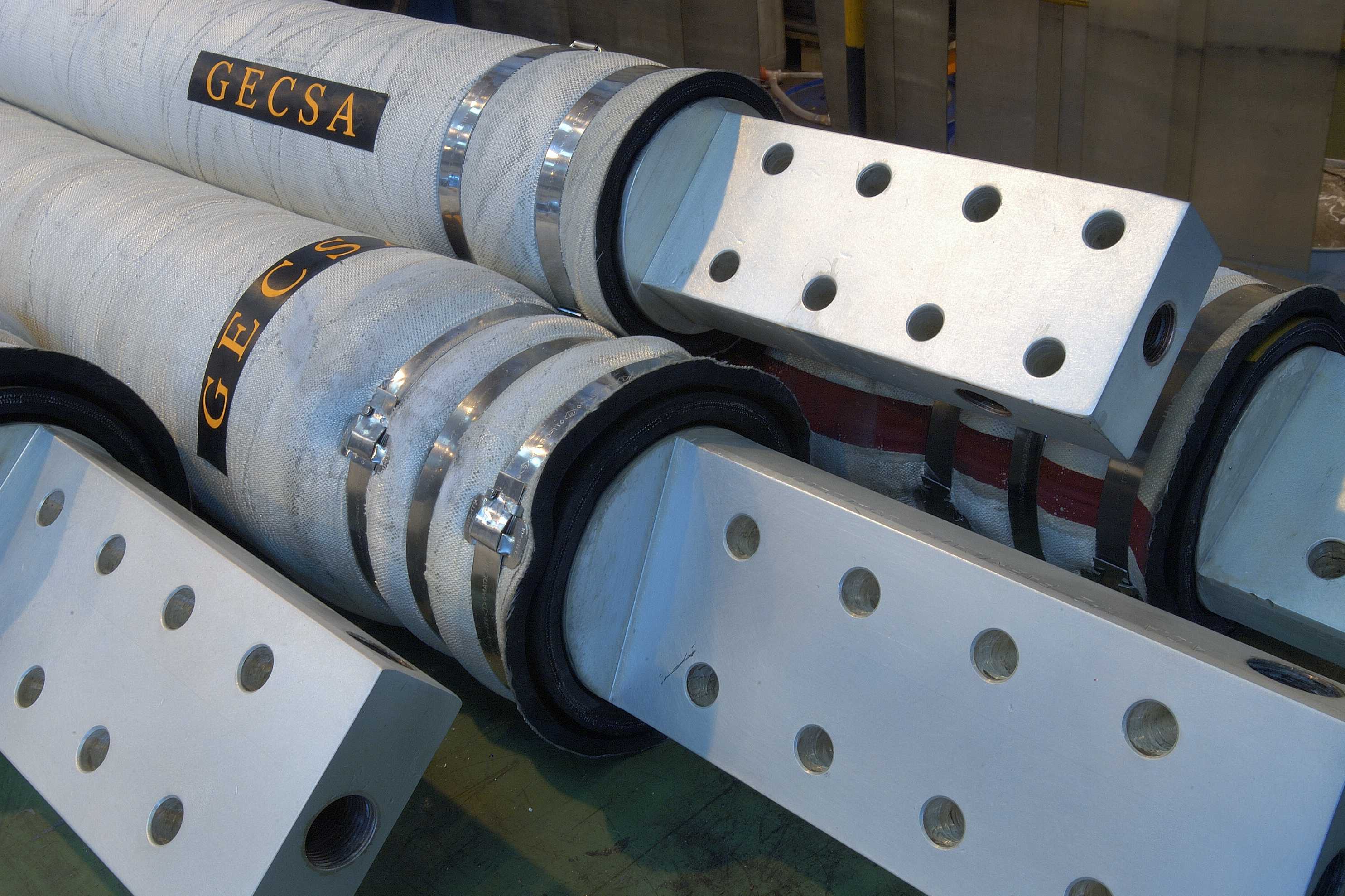

WATER COOLED CABLES

Made by rope lay technical with Ø0.5mm wire. Different protection depending the necessities of the furnace. High quality for a long life.

FLEXIBLE CONNECTIONS

Connections made of copper or aluminum, in sheet or braid. High flexibility connections for connection with the transformer or groundings.

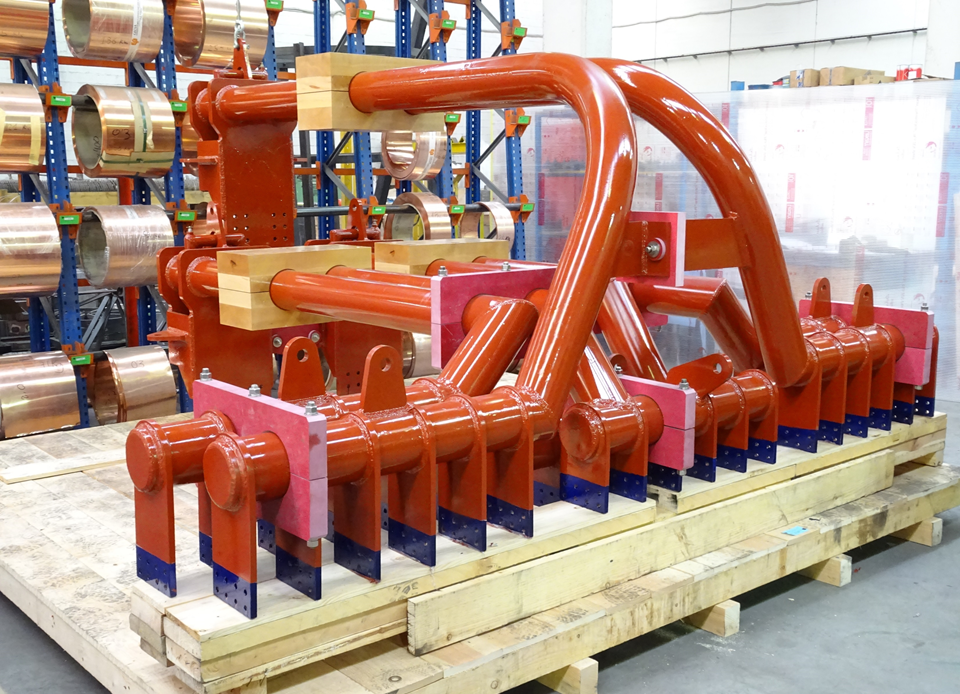

BURBARS

Delta clousure busbars for electric arc furnace and Laddel furnaces. Complete engineering, manufacturing and assembly. For new furnaces or revamping to new transformers

CURRENT CONDUCTING ARMS

The current conducting arms are manufactured like a copper conducting body where current is conducted to the contact shoes by the own arm body manufactured in bimetallic material with high electrical conductivity characteristics.

CONTACT PLATES/JAWS

Contact clamps for current arms made of laminated or forged electrolytic copper, ensuring the highest electrical conductivity and the ideal mechanical conditions for high resistant contact with the electrode. Gecsa offers service of reparation of maintenance by TIG copper welding.

INJECTION BOXES / KOYETS

Koyet boxes and carbon and oxygen injection equipment, manufactured by casting with the latest technologies for high reliability and functionality of the piece. Gecsa offers service of reparation of maintenance by TIG copper welding.

WATER COOLED PANELS

Panels for shells or vaults made on copper and steel

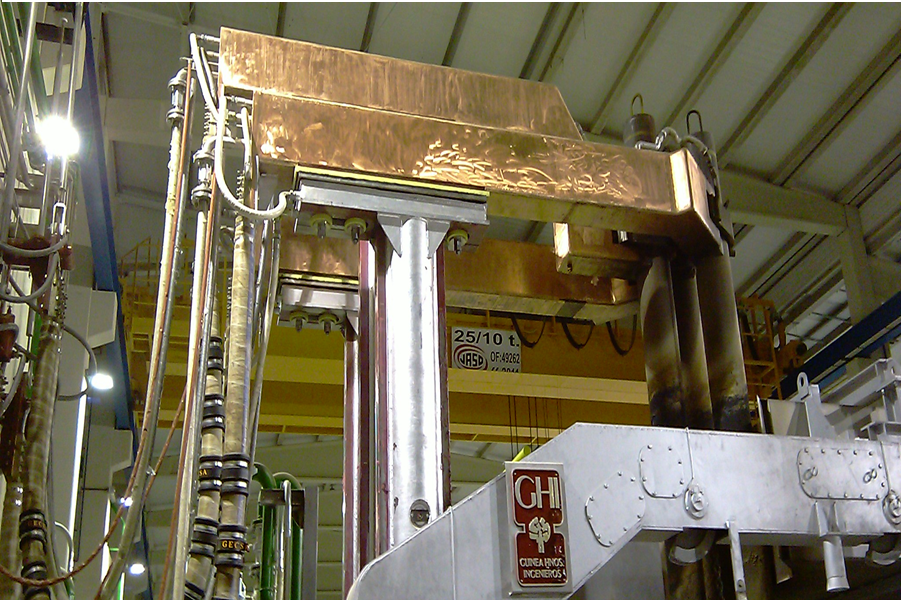

INSTALLATIONS

Specialized works on plant. Assembly of elements manufactured by Gecsa or electrical equipment as transformers.

Automatización

- Regulación y gestión de EAF

- Sistema de alimentación de aditivos

- AOD

- Horno de recalentamiento.

- Líneas de acabado

- Manejo y almacenamiento del producto

- Equipo auxiliar

- Sistemas de optimización de horno

- Soluciones 4.0

Department of Electrical Engineering

- Installations in medium voltage (Up to 72.5 Kv)

- Specific equipment for steel mills

- SIEMENS Vacuum Circuit Breakers specific for electrical arc furnace

- Capacitors

- Harmonic filters

- RC circuits

- Motorized disconnectors

- Power transformers, etc.)

- Furnaces and heaters of variable frequency up to 4 MVA.

- Energy saving and process optimization.

- Electrical Turnkey Project

- Technical Training