induction coils

Specialized in InductionFurnaces, supplying and giving maintenance to electrical equipment, control and regulation systems and electrical engineering for medium and low voltage

Induction elements

With more than30 years of experience manufacturing copper and aluminum busbar systems, our experts have been closed to specialist customers obtaining high knowledge about high current transmission. GECSA, company dedicated to the design, manufacture and installation of electric conductors of high intensities of copper and aluminum, also manufactures components for induction furnaces, both for manufacturers of equipment and for end users (foundries) or auxiliary companies that provide service. The specialization of GECSA in welding processes for copper, aluminum, stainless steels and their alloys using high intensity MIG and TIG procedures is noteworthy. Within the range of products supplied, the manufacture and repair of coils stands out, which is responsible for the production of the magnetic field in which the material is melted by electromagnetic effects.

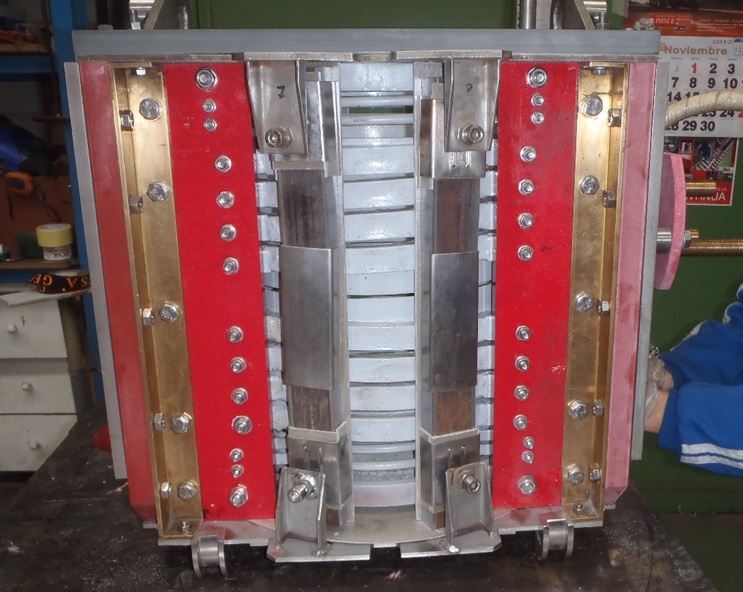

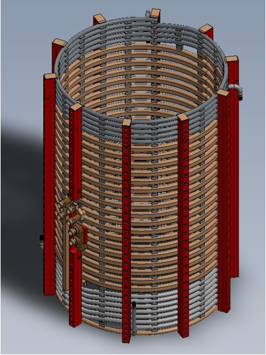

Coils for Crucible furnaces

GECSA manufactures and repairs induction coils, according to drawing. The coils are formed by a copper profile of different shapes and sizes depending on the design, circulating the flow of cooling water inside. Once the profile is formed, it is isolated by means of paints, varnishes and protections of various insulating materials. Previously, the cooling connection terminals will have been welded to the copper profile. Ultimately epoxy type materials are placed to insulate the coil from the boiler. The most frequentrepairs are the elimination of cracks and leaks. Also, measurement ofearth fault is made,checking isolation, as well as replacement ofthese. GECSA can supply refractory protections to install directly on furnace